Carbon fiber reinforced crack processing technology of highway bridge has been widely favored in recent years because of its advantages of simple construction and tight schedule. Most highway Bridges have visible or invisible cracks in the foundation beams because of their long service time or long-term overload operation. For general cracks, most of the use of carbon fiber material reinforcement can be. The following reinforcement home will introduce the reinforcement construction of carbon fiber cloth for bridge cracks.

The construction technology of carbon fiber cloth reinforcement for bridge cracks has the following three major processes:

The first step is to solve the bottom layer of the highway bridge

1. Repair structural cracks of glue grouting highway bridge foundation beams with cracks.

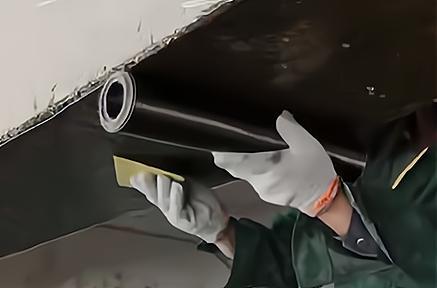

2. Eliminate the degraded positions of the concrete surface, such as shedding, loosing, honeycomb shape and erosion, and carry out cleaning, grinding and polishing. After the surface is dry and irritated, repair the convex and concave positions of the concrete surface with repair raw materials. If there are rough edges, use sandpaper to buff and polish. Find the plan of hand touch feel dry, can carry out the next process of engineering construction.

3. The Yin and Yang Angle of the carbon fiber cloth paste should be polished into an arc shape, and the Yin Angle line should be made up into an arc fillet to repair the raw material, and the arc half meridian should not be less than 25mm.

The second step, brush the base glue

1, the deployment of good substrate should be applied immediately, with a disposable soft brush or specially made roller will be evenly wipe the substrate on the surface of concrete, do not leak brush, flow or bubble. Check the glue surface after the base glue is dry and solid. If the glue surface has rough edges, use grinding sandpaper to polish and polish smoothly. If the glue is damaged, it should be brushed again and the next process can be carried out after dry and solid.

2. The next technological process should be carried out as soon as possible after the base glue is dry and solid. If the brushing time exceeds 7d, the original base glue should be clearly removed with the polishing machine and wiped again.

The third step, highway bridge foundation beam pasted carbon fiber cloth reinforcement construction technology and common problems

1. It is not suitable for engineering construction in rainy days or under gas damp and cold standards. If it is necessary to work on wet and cold prefabricated members, be sure to air dry the surface of the prefabricated members or use professional adhesives.

2, carbon fiber cloth paste should be carried out under the working temperature standard of 5~35℃, the use of adhesive should meet the requirements of the application of working temperature.

3. On the concrete surface to be strengthened, the construction and lofting shall be carried out according to the design drawing, and the position of each layer of chemical fiber polymer material shall be defined.

4. Cut carbon fiber cloth according to the specifications of the design scheme. The lap length of carbon fiber polymer reinforcement is not suitable for less than 100 mm, and the lap location of steel reinforcement should avoid the key bearing area. The cut fabric must be properly placed in a disc and numbered. Already cut chemical fiber polymer materials should be applied as soon as possible.

5. Before pasting carbon fiber cloth, wipe the concrete surface again to ensure that the pasting surface produces dust. When brushing adhesive on the surface of concrete, the colloidal solution should not flow; Colloid solution brush out not to control the line; Brush evenly.

6, paste inside the chemical fiber polymer material, should be carried out in accordance with the order of the rise. The carbon fiber cloth is extruded from one end to the other with a roller barrel to remove the bubble between the colloidal solution and the chemical fiber polymer material, so that the colloidal solution penetrates into the chemical fiber polymer material, moist and smooth. The barrel used should not cause electrostatic effect in the whole process of extrusion forming.

7, elected with several strips or double layer of chemical fiber polymer material reinforcement, in the former layer of fiber cloth surface touch fingers feel dry, immediately coated adhesive paste after a layer of chemical fiber polymer material.

8, the final layer of chemical fiber polymer materials engineering construction is completed, on the surface of the symmetrical wipe a layer of penetration epoxy resin (the overall surface layer safety

https://www.heatresistcloth.com/carbon-fiber-fabric/

Post time: Apr-18-2023